European confectioners reluctant to pay premium for hygienic machines

“In Europe, what I’ve seen is that everybody wants this design but they don’t want to pay for it,” Marc Horna, senior engineering manager for machine supplier Hosokawa, told ConfectioneryNews.

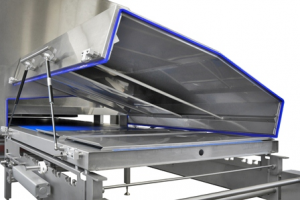

Hosokawa Bepex, the firm’s confectionery division, unveiled its new equipment at Interpack in May after overhauling its entire portfolio so designs matched the exacting hygiene standards of the meat industry. It followed a salmonella scare at one of its confectionery customers’ factories in the US.

“The US customers, we were driven by them, and they are willing to pay more money for it,” said Horna.ButEuropean confectioners have been put off by the price tag leaving them exposed to contamination risks, he said.

Running the risk

Although incidents of contamination are rare – there were only 51 confectionery recalls in 2013 in the UK for example – the risks are grave.

Cadbury’s 2006 recall in the UK over salmonella-contaminated chocolates cost the company about £20m ($34m) and it also pleaded guilty to criminal charges for which it was handed a £1m ($1.7m) fine.

In another incident, peanut supplier the Peanut Corporation of America went out of business after a salmonella outbreak at its plant led to nine deaths and over 700 illnesses across America. A host of confectionery firms were affected including Theo Chocolate, Brown & Hanley’s and Jelly Belly.

‘It’s a question of saving the world’

Horna said it was safer to take all possible precautions despite the added cost. “Most customers say that they don’t calculate with recall risks, but it’s a question of saving the world. You need less chemicals, less water, you produce a longer shelf-life of the product because you have more sanitary conditions in the whole line.”

He said that European attitudes may change naturally over time and could be accelerated if costs became price neutral or European regulations forced changes.

Some machines pricier

He said that individual pieces of hygienically designed equipment that used stainless steel may be more expensive than the older versions, but Hosokawa’s entire line was on par with its older version.

“The cooling tunnel is much more expensive because you have to weld everything – in the past we didn’t do that. In the past, in the cooling tunnel you had aluminium inside and if you use aggressive chemicals this will destroy the aluminium”

Changing practices

Horna said that those that do buy hygienic designs should take nothing for granted.

“It could be that you get a hygienic machine for the same price, but the whole process costs much more money. This is dangerous if you don’t calculate. You say you want a hygienic machine but you do not think about all the installations, the building and the people who need to be trained to think hygienically.”

He said he had seen customers buy hygienic machines but then have substandard installations by a local electrician. “They spend a lot of money and it’s not worth it.”